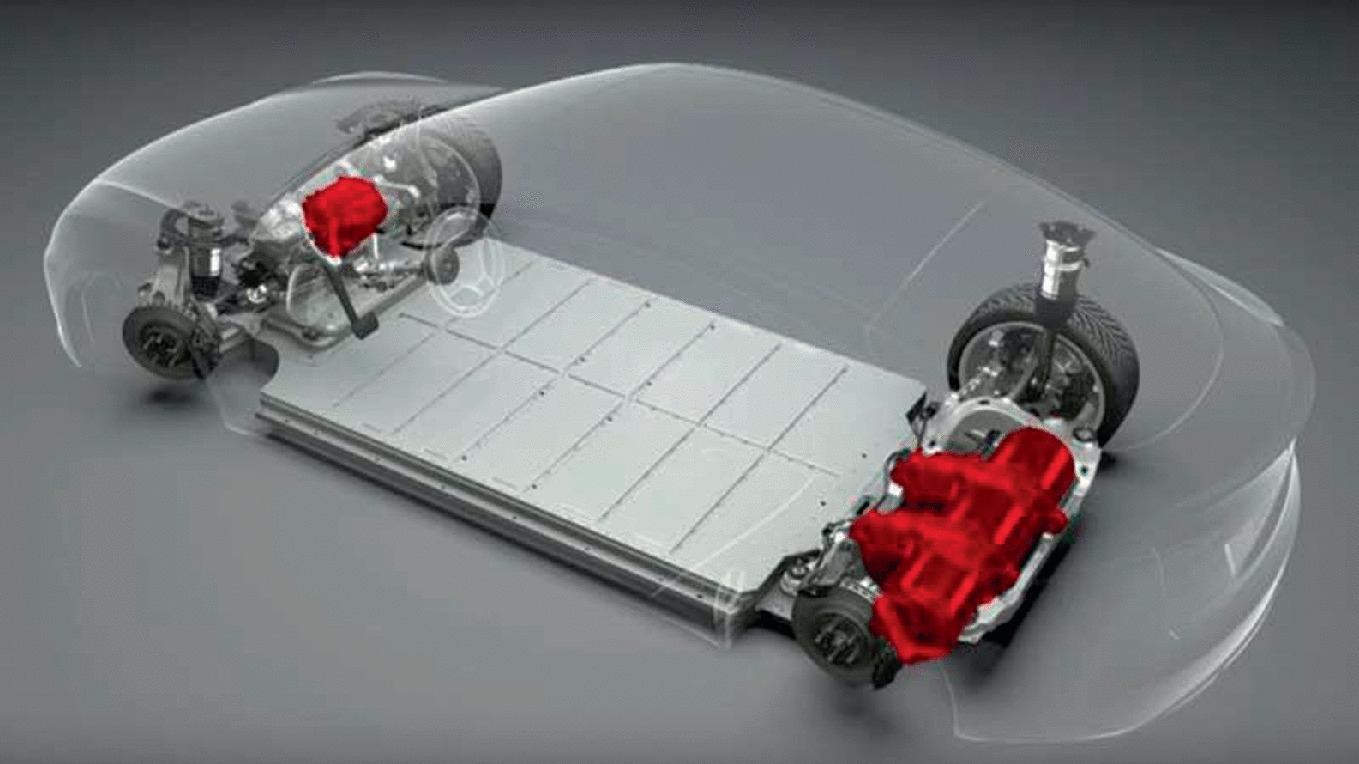

There has been a sharp

rise in the demand for electric vehicles all over the world. This shift has

brought major changes to automotive manufacturers and their supply chains.

Lightweight manufacturing is a major theme, i.e., the lighter the vehicle, the

less energy it consumes. This ultimately has led to a change in requirements

for pines tubes benders, with a growing demand for compact and high-performance

components. A popular automotive manufacturing process is to use pines tube

benders to bend round tubes and bring them to the final shape via hydroforming.

This process is suitable for steel alloys.

The pivot towards

electric mobility is also leading to a change in the designs of pines tube

benders parts. The conventional pines tubes benders’ machine with predefined parameters is being

replaced by product-centric customizable pines tubes benders. Bending

performance, geometric measurements like tube length and bending radius, and

tool installation space are all aligned to conform closely with the

manufacturer’s specific processes and product requirements.

While the pines tubes

benders parts are easily available in the market, building a customized machine

is very difficult. Also, with intensifying competition, short turnaround cycles

and extreme accuracy are more important than ever before. Pines tube benders fabricators that have in-house processes are

likely to adapt to relentless cost pressure by seeking high-performance

machines tailored to their needs. A modern pines tubes benders should deploy a

multi-level technology strategy that encompasses features such as customizable

multi-radius bending tools. Such machines allow for simple and accurate bending

with an extremely short length of tubes between bends.

Post a Comment